American-made since 1960

Wire Mesh Welding Services

Angola Wire is your go-to provider for high-quality mesh welded products. With our expertise and advanced equipment, we specialize in creating welded wire mesh panels for a variety of industries and applications. Whether it’s construction, fencing, agriculture, industrial storage, filtration systems, or more, we have the capability to meet your wire mesh welded product needs.

Request a Quote

Here’s why Angola Wire is the ideal choice for your mesh welding products:

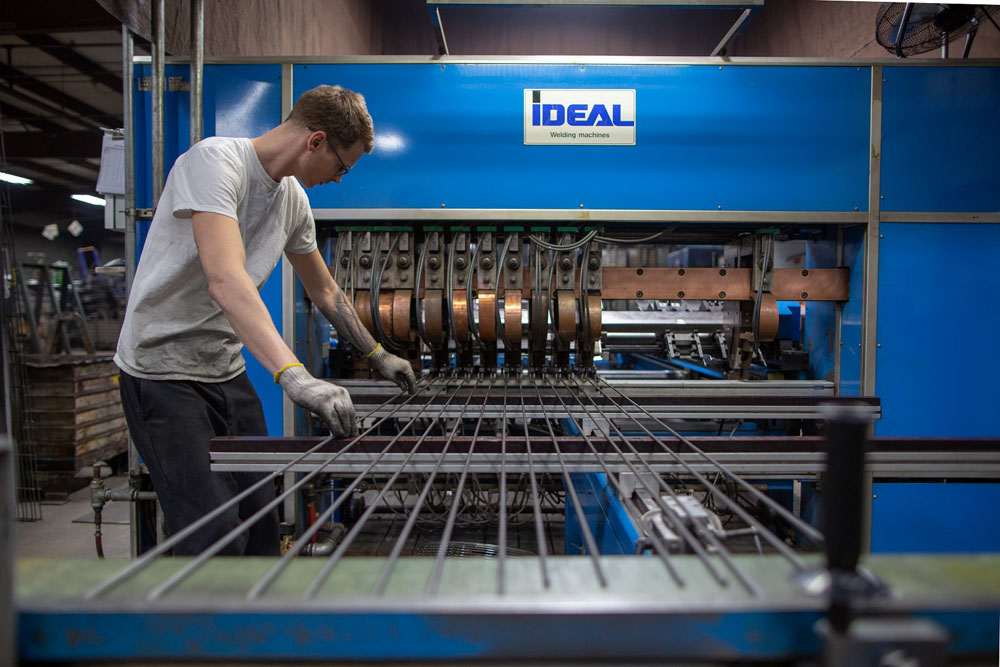

- Advanced Mesh Welding Technology: Our state-of-the-art mesh welding machines are equipped with cutting-edge technology and computerized controls to offer automated mesh welding services. These machines ensure precise wire positioning, uniform wire spacing, and consistent weld quality. With the ability to program parameters such as wire spacing, welding current, and welding time, we deliver welded wire mesh products that meet your exact specifications.

- Wire Selection and Preparation: We understand the importance of wire selection for optimal mesh performance. We work with various materials such as steel and stainless steel, choosing the appropriate wire diameter and material based on the desired strength, durability, and application requirements of the final mesh product. Our meticulous wire straightening and cutting processes ensure uniform wire lengths and facilitate smooth manipulation during the welding process.

- Expert Machine Setup and Programming: Our experienced technicians meticulously set up the mesh welding machines, installing the necessary wire guides, welding electrodes and specifying the desired mesh size. The machine’s computerized controls are programmed with precision, ensuring accurate wire positioning and consistent weld quality throughout the mesh.

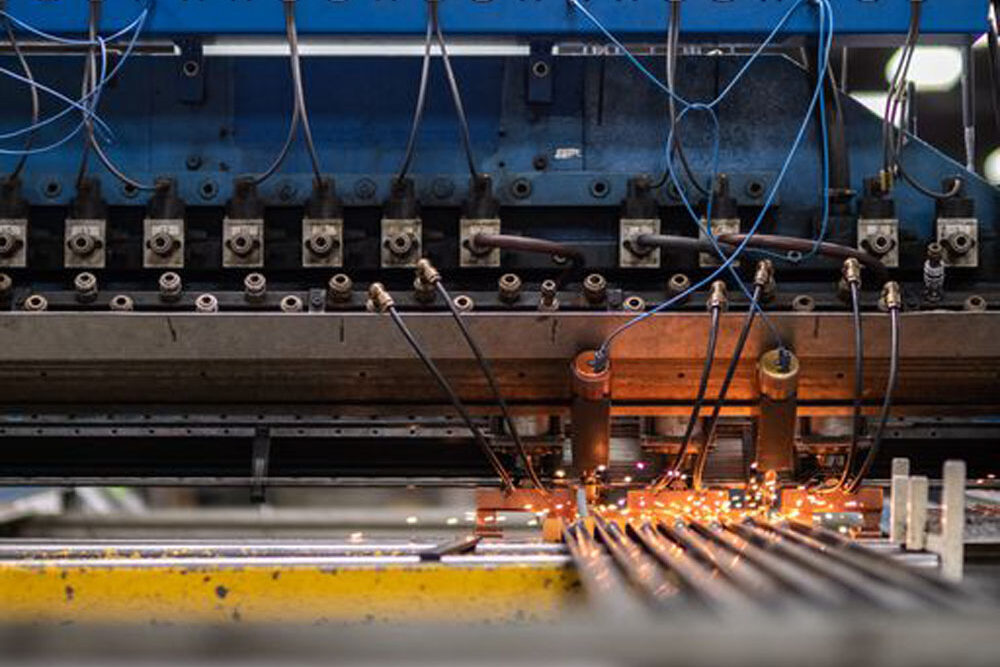

- Efficient Welding Process: Once the machine is set up and the parameters are programmed, the mesh welding process begins. Our machines position the wires precisely according to the programmed specifications. Electrical current is applied, generating heat through resistance and causing the wires to fuse together at the intersecting points. The welding electrodes exert pressure, ensuring proper contact and bonding. Our efficient welding process ensures uniform spacing, alignment and structural integrity of the welded wire mesh.

- Quality Control Assurance: We prioritize quality throughout the mesh welding process. Our skilled operators conduct thorough inspections to ensure that the final welded wire mesh meets the required specifications and standards. We perform visual inspections, measurements of wire spacing and dimensions, and testing for strength and durability. Our commitment to quality guarantees that you receive a reliable and high-quality product.

- Versatility and Application: Welded wire mesh finds applications across various industries and sectors. Whether you need mesh for construction projects, fencing solutions, agricultural applications, industrial storage, filtration systems, or any other industry, our mesh welding capabilities can fulfill your specific requirements. We offer customization options for mesh size, shape, and configuration to meet your unique needs.

The Angola Wire Advantage

When it comes to mesh welding, Angola Wire is your trusted partner. With our advanced technology, technical expertise, and commitment to quality, we deliver exceptional welded wire mesh products tailored to your specific requirements. Contact us today to discuss your mesh welding needs and experience the Angola Wire advantage in precision manufacturing.

As a third-generation family-owned business, we understand the importance of relationships. Our service team takes pride in its commitment to our customers.